HeiMAX

Assistance systems

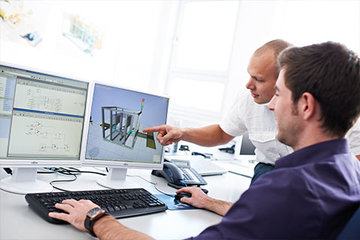

Machines and plants require regular maintenance, and defective parts have to be replaced quickly. Maintenance checklists are often available only on paper, technical documentation isn’t readily accessible, and parallel activities are difficult to coordinate.

HeiMAX (HEITEC assistance systems) ensures an optimal, demand-driven, and paperless maintenance workflow for planning, coordination, and performance of maintenance and repair work. In the process, the web-based software communicates with all higher-level systems used in the company (SAP, CAD, etc.). As a result, service employees always have access to all the necessary information at the right time and in the right place.

HeiMAX in action

Has this happened to you? You’re standing in front of the plant that requires maintenance holding a stack of folders with operating instructions, checklists, and wiring diagrams. The wrench for inspection point 7 doesn’t fit, and you have to add this to your notes.

Imagine if your service technicians completed plant maintenance up to 40 percent faster. Less-qualified personnel can also easily learn the new software and perform maintenance tasks independently.

News

April 26, 2017

HeiMAX - maintenance assistant

HEITEC is presenting HeiMAX, a maintenance assistant, at Interpack in Düsseldorf.

HeiDetect Wheel Robot – a robot ensures perfect rims

In the HEITEC group, HEITEC PTS is mainly active in the robotics and automation industry. Take, for example, the “HeiDetect Wheel Robot” fully automatic wheel test facility that inspects cast aluminum rims for defects.